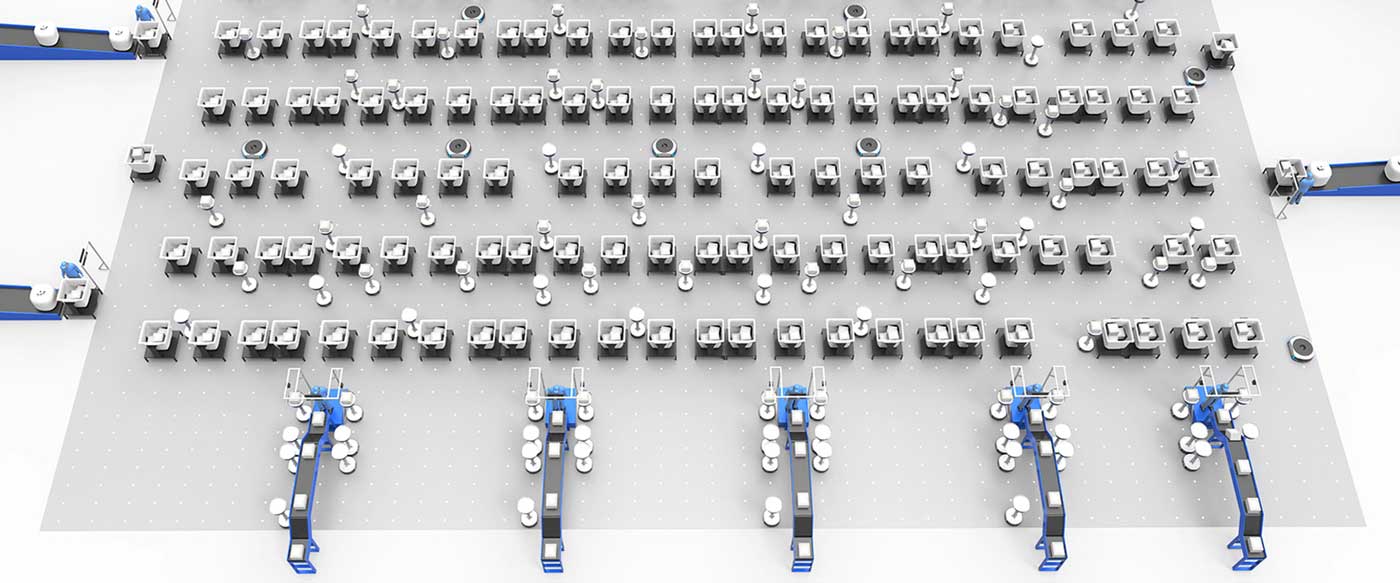

Geek+ Floor-based Sorting solution uses S20 series robots to sort small or middle-size parcels at the floor level. Empowered by strong algorithm, the solution monitors robot traffic and balances the task of each robot to achieve maximum sorting efficiency. It can be integrated with Geek+ moving robots to automatically transport packages and achieve unmanned automated sorting operations.

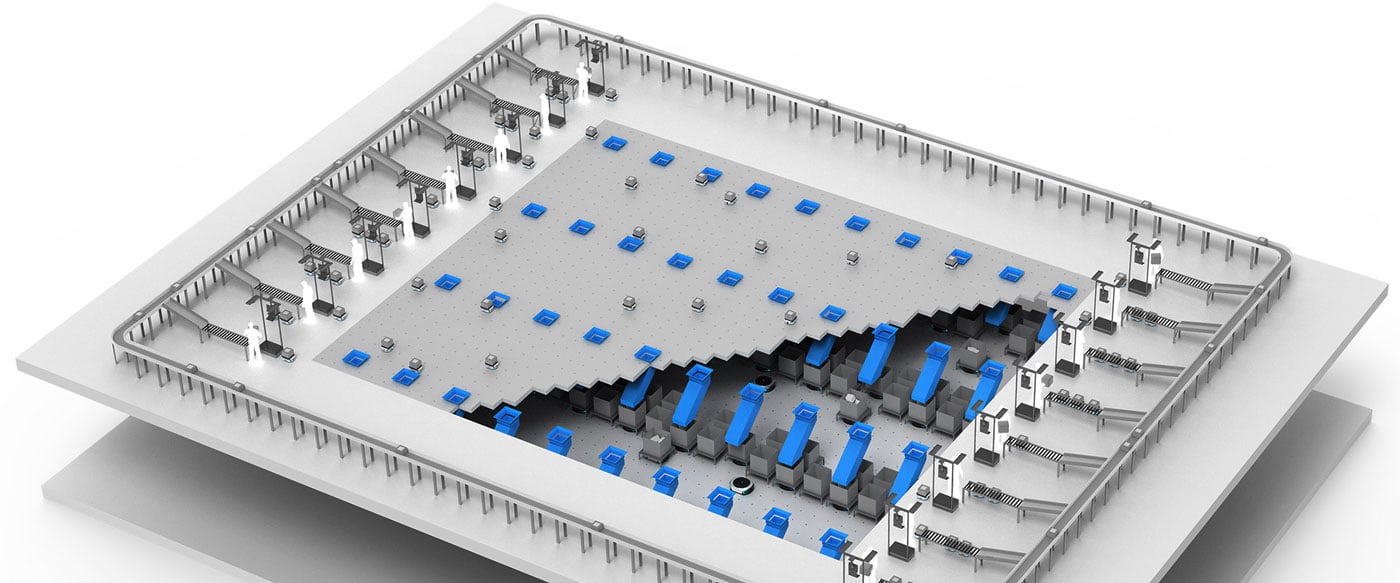

With Multi-layer Sorting solution, the robots work on different level platforms, improving efficiency and utilization of warehouse space. Packing, sorting, and loading areas are highly integrated, optimizing the whole outbound process, realizing unmanned sorting operations.

Geek+ Sorting System is suitable for goods and parcel sorting, applicable to retail, apparel, pharmaceutical, 3C, FMCG, postal delivery, and other industries. Common sorting applications include:

Store replenishment and cross docking

Multi-combination with picking

Expanded sorting capacity

Goods return and book return sorting

Sorting after packing

Central distribution center parcel sorting