Third Party Logistics (3PL)

Built for 3PL speed. Ready for any client.

Juggle SKUs, SLAs, and volume spikes seamlessly. Geekplus helps 3PLs run lean, scale fast, and win more clients with automation that adapts to any order flow.

300+

3PL Projects Worldwide

<4x

Increased Throughput

56,000+

Robots Deployed Globally

10,000+

Tasks per Second Handled by RMS

What Our Customers Are Saying

.png)

Thanks to good teamwork and fast communication, all challenges in the project could be handled efficiently.”

Alexander Quercher,

Project Manager of Rhenus Logistic

.png)

The Geek+ solution is a great fit for our operation in Grobbendonk, providing a more comfortable working environment for on-site employees."

Bart Beeks,

Global Head of Contract Logistics of CEVA

.png)

As our business grows, Geekplus’s sorting system has enabled us to manage increasing volumes quickly and efficiently."

Dongseop Yoon,

Senior Business Development Executive of Toll

.webp?width=2000&name=geek+_toll-03%20(1).webp)

.png)

Relying on cutting-edge technology provided by Körber, together with partners like Geek+, has helped us to maintain an efficient flow of goods, enhanced shipping performance, and reliability in light of the steady growing pressure of customer demands. "

András Táncsics,

CEO of Boxy

.png)

Automation has really helped us to be more flexible in being able to adapt to customers’ ever changing order profiles and growth. We went into Cyber Monday clean and received tons of praise from our customers. "

Thomas Stearman

Director of Industrial Engineering, UPS Supply Chain Solutions

We understand Your Challenges

From multi-client cold chain logistics to ecommerce fulfillment, we help you handle client complexity, space constraints, labor volatility, expanding SKUs, flash sales, reverse logistics and more with ease.

Demand Volatility

Unpredictable order fluctuations during low or peak season, flash sales and promotions.

Multi-client & Multi-category Picking

Different rules, SKUs, and SLAs per client, hard to standardize.

Order Consolidation and Last-mile Prep

Final staging is slow, messy, and hard to track.

High-volume Reverse Logistics

Handling and tracking returns is messy and labor-intensive.

SLA Pressure

Missing a promised delivery window can cost you the client.

Low Profit Margins

Every inefficiency eats into already tight profits.

Space Utilization

Are you paying for air? or Are you utilizing every inch of space?

Tech Fragmentation

Too many systems. Multiple vendors. Zero integration.

Solutions for Every 3PL Challenge

Geekplus Goods-to-Person systems automate your full fulfillment flow, from pallets to pieces, with real-time control across zones and clients.

Win your End Client's approval. We'll help you prove it.

Your One-stop Partner

for Warehouse Robotics

Built for Every Scenario in 3PL

Every client brings their own channels, rules, and delivery promises. We help you switch between them without switching up your operation. From retail pallets to DTC parcels, Geekplus helps 3PLs run everything through one streamlined flow.

B2B & B2C in One Facility

Support enterprise and consumer clients side-by-side.

Assign robots, zones, and rules per client or order type while maintaining full visibility.

Higher margin per m², fewer constraints.

Return Processing

Speed up returns with fewer errors.

Geekplus helps you reintegrate inventory quickly, with automated quality checks and optimised storage allocation.

Faster resale, lower labor effort.

Cross Docking

Move goods between docks with zero time wasted.

Robots transfer incoming stock directly to outbound staging zones, no long-term storage required.

Maximise flow-through

Omni Channel

Fulfill retail B2B, B2C, and DTC from one setup.

Our systems manage complex order profiles and route tasks based on channel priority.

Unified operation, seamless fulfillment.

Sortation

Automate SKU, brand, or destination-level sorting with minimal effort.

Geekplus robots and software dynamically group parcels for efficient packing and shipping.

Lower error rate, faster outbound.

Built for Every Warehouse Process in 3PL

Seamless integration of all processes for 3PL industry. Reduce operating cost per order by up to 40-50%, and increase throughput by 2–4X without touching your building structure.

Seamless integration of all processes for 3PL operations.

Inbound/Put away

- Client-specific receiving rules

- Smart slotting by volume, velocity, and value

Storage Optimization

-

Store more per m² while keeping fast movers accessible

-

Slot SKUs by velocity, size, and handling needs.

Picking

-

Goods-to-Person batch, zone, or wave picking

-

Multi-client and multi-SKU compatibility

Order Consolidation & Staging

-

Group SKUs across zones into single orders

-

Prioritize by SLA, carrier, or ship window

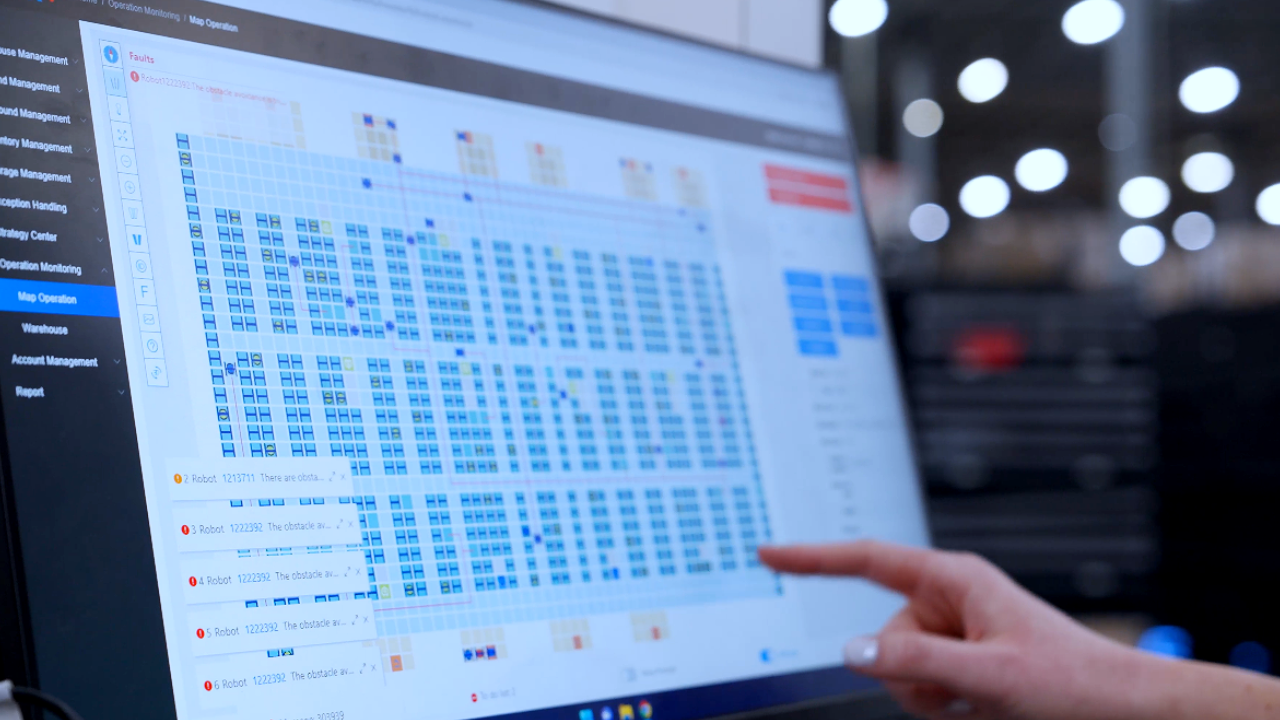

Real-Time Visibility and Control

- Real-time dashboards

- SLA tracking for each individual client

Quality Control

- Geekplus Robots contribute to improved traceability and documentation of quality control processes

Outbound & Handover

-

Auto-sort by route, dock, or delivery type

-

Labeling and dispatch prep built in

Inventory Replenishment & Accuracy

-

Real-time counts

-

Auto-replenish forward pick zones

Built for Every Storage Type in 3PL

Every 3PL warehouse deals with mixed inventory from bulk pallets to individual pieces. Geekplus systems adapt to your SKU profile, allowing flexible storage and picking of pallets, totes, and pieces within a single system.

Storage Types

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

Item Sizes

.png?width=333&height=232&name=Group%20237747%20(3).png)

Item Types Handled

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

Everything you need to win over your End Client in one kit.

Includes industry and solution brochures, videos, case studies, and other tools to make the case for automation.

Why 3PL Operators choose Geekplus?

Modular by design

Launch fast, expand when ready

Works with any WMS

No full rip-and-replace needed

Fast payback

Typical ROI in 2-3 years

Global support

40+ countries, multi-lingual ops teams

Client-level visibility

Show your customers real-time data they’ll love

3PL Success Stories

Let's turn your warehouse into a growth engine 🎯

Reach out to our team for enquiries, sales, virtual demo, live demo, or anything you need to get started.

Downloads

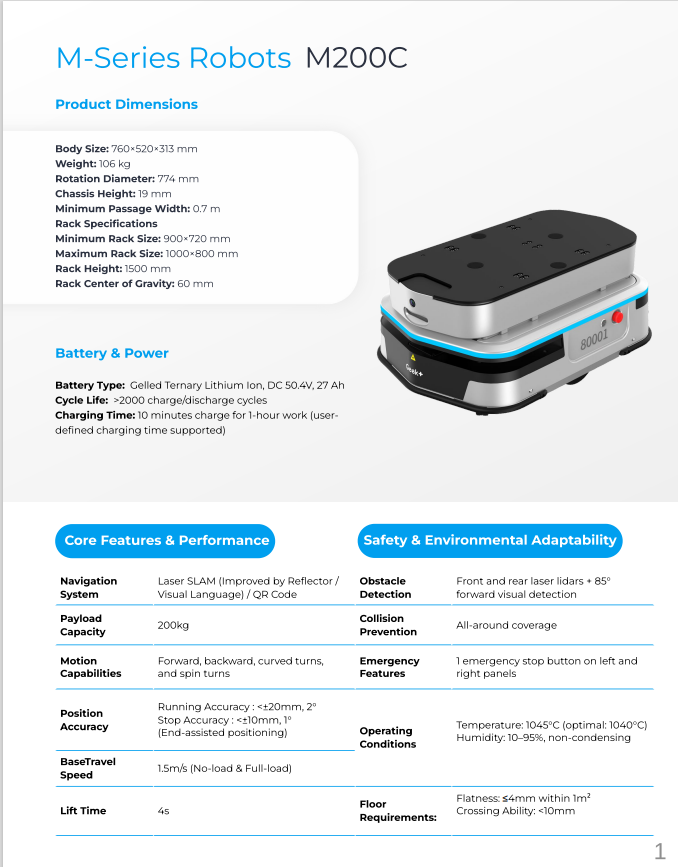

F Series Product Fact Sheet

27 January, 2026

S Series Product Fact Sheet

27 January, 2026

M Series Product Fact Sheet

27 January, 2026

FAQs

Geekplus solutions greatly reduce operational costs by automating labor-intensive processes like sorting, picking, and replenishment. This results in faster order fulfillment, fewer errors, and up to 300% increased efficiency, enabling a typical ROI within two years.

Deployment is exceptionally fast, with a timeline 1.5 times quicker than competitors. Depending on your warehouse size and complexity, setup can be completed in as little as one to three months, ensuring minimal disruptions to your operations.

Geekplus offers modular systems tailored to 3PL challenges, including multi-client workflows, peak load surges, and high-volume reverse logistics. Solutions like real-time dashboards, SLA client tracking, and collaborative robots ensure seamless operations and unmatched scalability.

Geekplus systems are designed to scale effortlessly. Add robots, storage, or workstations as your client base or order volume grows, ensuring you can adapt to changing demands without infrastructure changes.

Geekplus solutions are ideal for industries like eCommerce, retail, healthcare, and cold-chain logistics. They excel in environments that require handling diverse SKUs, fast order turnarounds, and complex, high-volume workflows.

These refined FAQs emphasize key decision points like return on investment, speed, and scalability while highlighting the unique value Geekplus offers to 3PL operators.

Related articles

Geek+ RMS Major Upgrade: Redefine ...

12 February, 2026

How to Optimize Warehouse Space with ...

11 December, 2025

.webp)

.webp)

.webp)