.png)

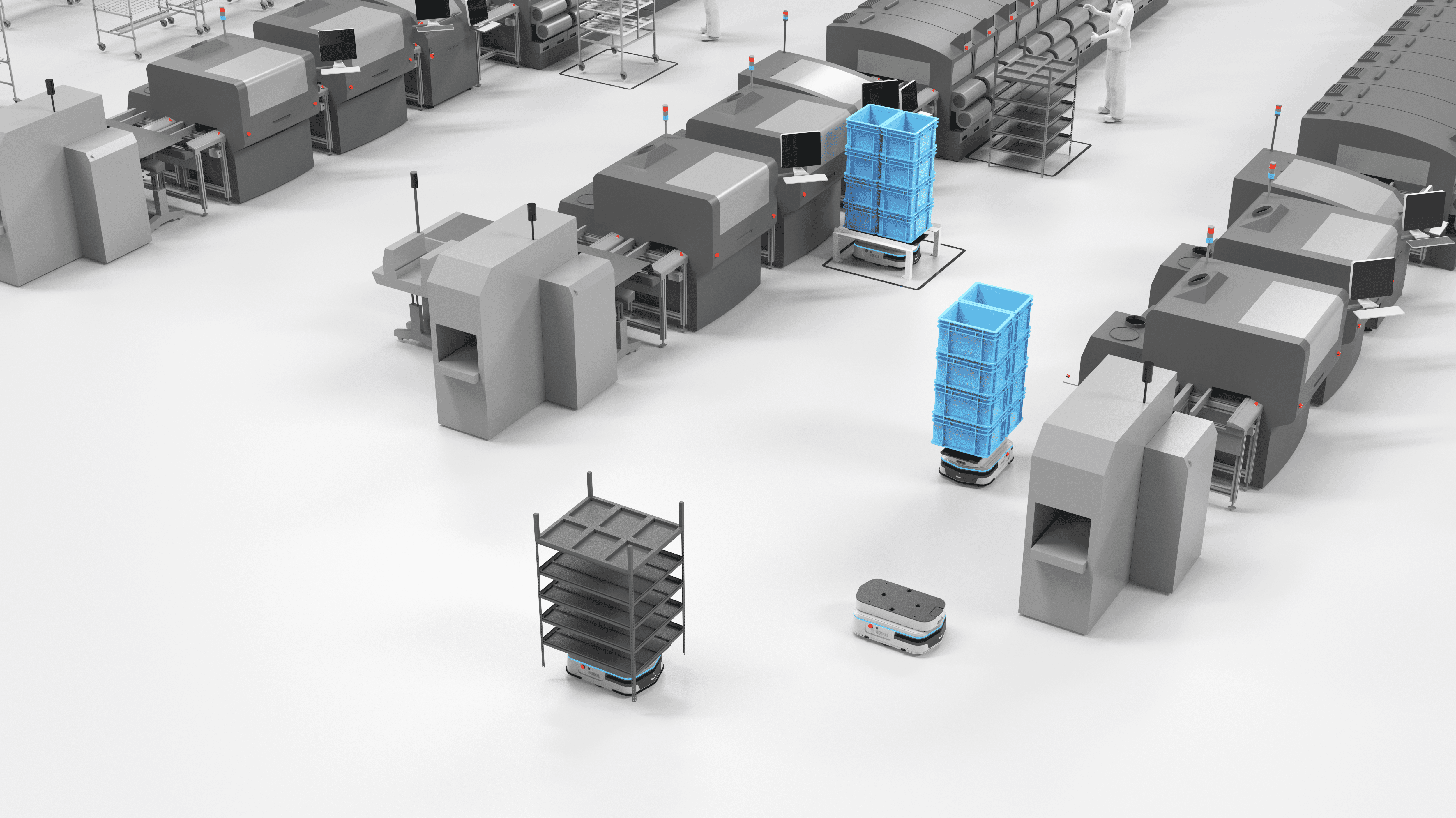

Tote is a very common carrier form in manufacturing and warehousing scenarios, often used to store small workpieces, materials etc. The Geek+ tote handling scenario provides an efficient and flexible distribution solution. The mobile robot, supported by a stationary base, can handle multiple standard size totes simultaneously, utilizing SLAM technology for autonomous navigation and distribution within factories and warehouses, eliminating the extensive installation of floor markers.

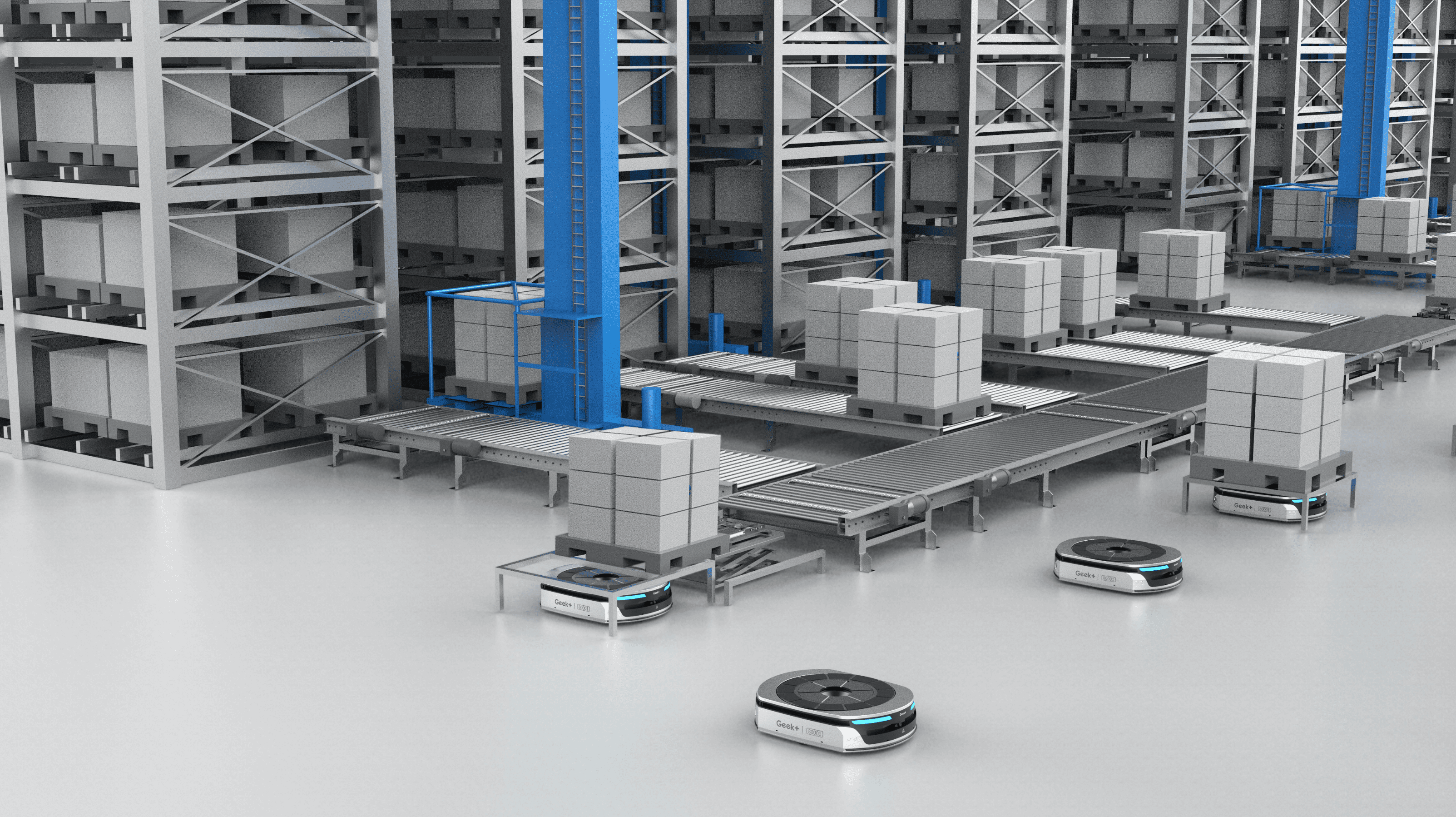

Geek+ can provide pallet lifting and handling solutions with a maximum load of 1000kg, MP1000R can handle pallet shelf, or handle pallet directly from the ground support. It is compatible with standard pallets of multiple sizes and shapes, basically covering all pallet handling needs in manufacturing and warehousing scenarios. The robot can support flexible customization of lifting modules within a certain height range to adapt to docking modules of different heights, such as load shifting and automatic conveying lines, to realize AMR applications in complex scenarios and help customers to lean production and efficient storage.

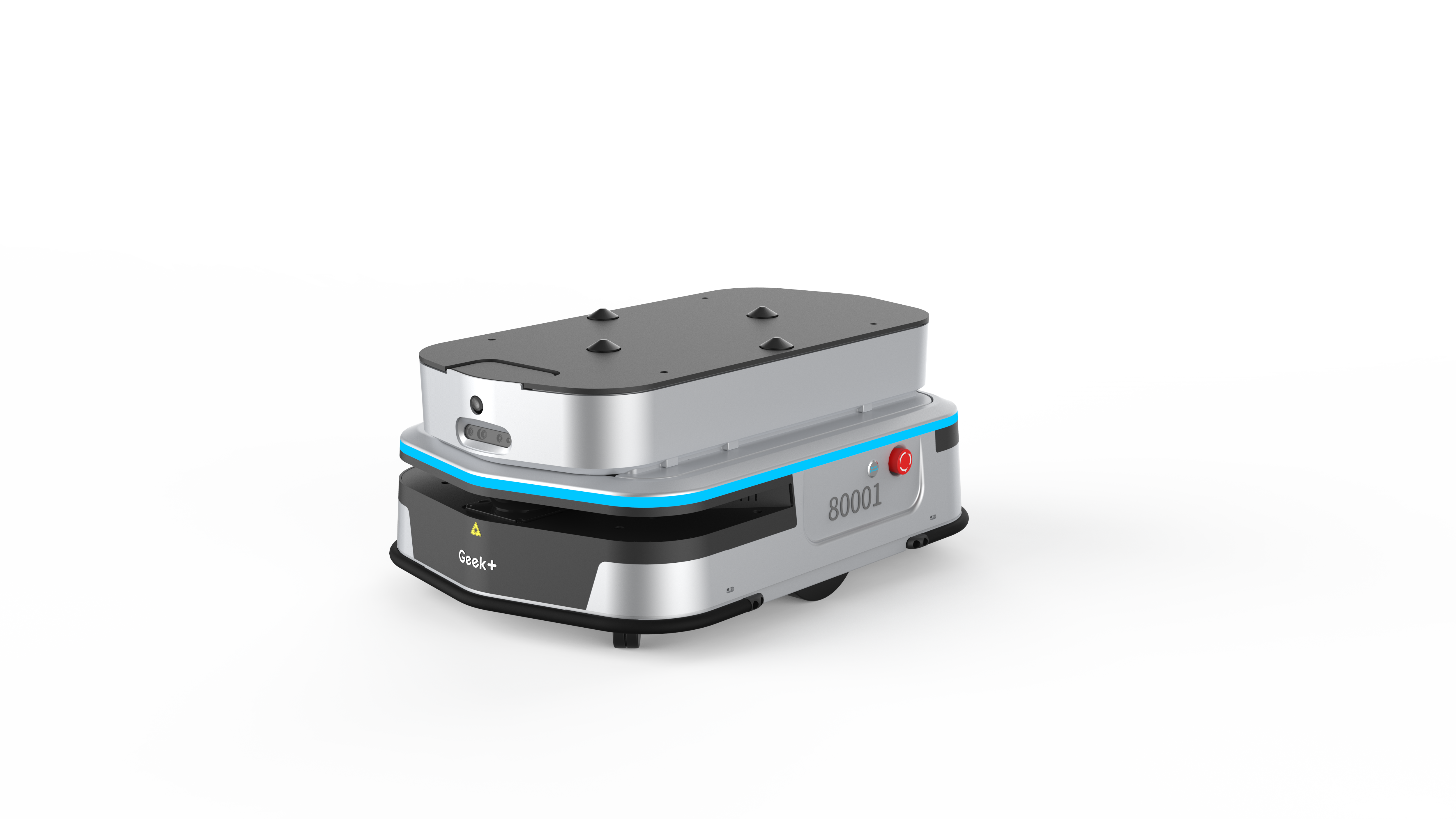

MP1000R and M200C can support various carriers such as shelf, rack, material cart, etc. The robot is efficiently compatible with loading and recording various shelf models, enabling automatic identification and fast docking. The robot is equipped with SLAM and QR code hybrid navigation technology to enable flexible deployment for complex and dynamic field environments, as well as sensors and algorithmic strategies such as LIDAR and visual cameras to ensure reliability and safety when delivering shelves and interacting with people.

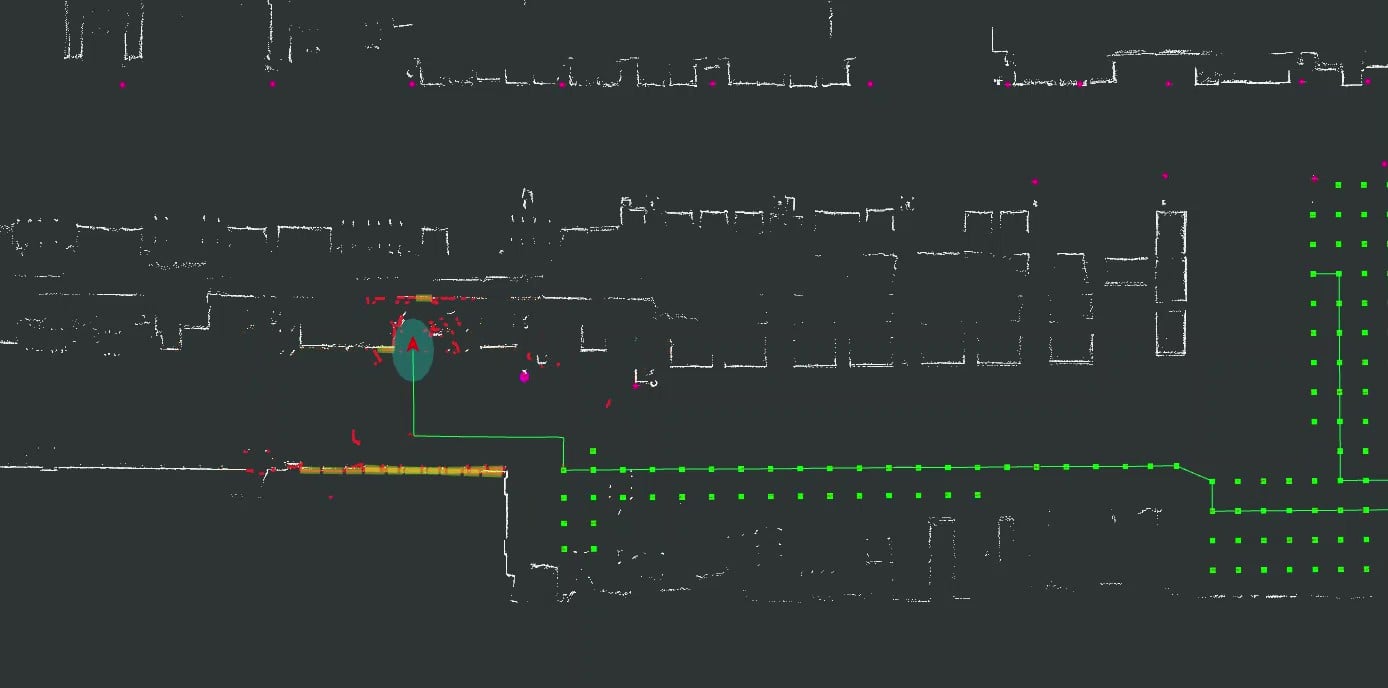

The Geek+ smart moving system (GMS) can be used for the setup and management of all kinds of logistics handling processes and tasks, as well as for the scheduling and operation of large-scale, multi-type robots.

It is equipped with key functions such as map editing, task editing, map monitoring, parameter configuration, robot management and log management, and can be seamlessly connected to robot management systems and customer business systems.

The system can schedule multi-type robot in a same site, and achieve optimal path planning, traffic control, cross-floor distribution, etc. The system is designed for ease of use and straightforward deployment, successfully coordinating the operation of hundreds of robots at a single location.

Geek+ moving robots can support both QR code navigation and SLAM navigation, switching to the most suitable one based on the working condition. SLAM navigation enables location and mapping in real-time using laser and camera sensor fusion. With SLAM, robots can maintain good positioning and motion control in a complex environment. With QR code navigation, the robot can travel fast following an accurate path.