Apparel & Fashion

Make Fashion Move Faster

Smarter warehouse automation for apparel and footwear fulfillment across B2B, DTC, and omnichannel retail.

From fluctuating demand to peak season readiness – we bring speed, space, and scalability to your apparel supply chain.

30+

Global Apparel Clients

1.5x

Faster Deployment Compared to Competitors

40,000+

Robots Deployed Globally

10,000+

Tasks per Second Handled by RMS

What Our Customers Are Saying

.png)

With the establishment of this center, Adidas aims to ramp up supply chain responsiveness, boost operational efficiency, and elevate the consumer experience."

Harm Ohlmeyer,

Global Chief Financial Officer of Adidas

.png)

Working with Geek+ has been a positive experience for us, both from the start and with the ongoing support provided."

Liam Jenkinson,

Site Manager of NEXT

We understand Your Challenges

Apparel brands face constant pressure to respond to fast-changing trends, shorter product cycles, and higher customer expectations for speed and sustainability. Traditional operations can’t keep pace with the need for agility and precision.

Peak Load Surges

Geek+ robots provide the ultimate solution for the massive volume spikes seen during Black Friday and other peak periods

Multi-client & Multi-category Picking

Geekplus robots collaborate with humans in the warehouses.

Parcel Consolidation and Last-mile Prep

Geekplus robots collaborate with humans in the warehouses, improving efficiency with combined precision and dexterity.

High-volume Reverse Logistics

Enable efficient coordination, accurate inventory management, and proactive decision-making with software integration.

Smart Solutions for Every Apparel Challenge

All powered by our Warehouse Execution System (WES) and Robot Management System (RMS)—to give you real-time visibility and orchestration across zones and clients.

You need to convince your End Client. Let us make that easy for you.

Ideal for

Apparel distribution centers

Retail & e-commerce fulfillment

Omnichannel logistics hubs

Multi-brand operations

Seasonal warehousing

& more...

One-stop Partner

for Warehouse Robotics

Built for Every Scenario in Apparel & Fashion

Every client brings their own channels, rules, and delivery promises. We help you switch between them without switching up your operation. From retail pallets to DTC parcels, Geekplus helps 3PLs run everything through one streamlined flow.

Flat and hanging pick in one system

Combine SKUs with different formats in a single flow

Returns and resale rebin

QC, re-slot, and put back without interrupting outbound operations

.png?width=1920&height=1080&name=apparel--return%20(1).png)

Peak season handling

Increase throughput with same workforce and layout

Store and eCom orders in parallel

Route by store, region, or final-mile destination

Style/size/color complexity

System matches product specs to optimize pick and load

2B/2C hybrid setups

Consolidate by zone, merge by tote or carton

Built for Every Warehouse Process in Apparel & Fashion

Seamless integration of all processes for 3PL industry. Reduce operating cost per order by up to 40-50%, and increase throughput by 2–4X without touching your building structure.

Inbound & putaway

Including hanging items

Storage optimization

By SKU velocity, category, and packaging

Piece and case picking

With ergonomic access

Sortation

By style, store, or size

Consolidation

Of different zones

Outbound staging

By SLA or transport route

Returns processing

With direct resale flow

Storage types handled by Solutions

No two warehouses are alike. STP tailors itself to your unique footprint, SKU mix, and throughput targets—seamlessly handling every size, shape, and even the most irregular items.

Storage Types

Handled with Shelf-to-Person Solution

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

Item Sizes

Multiple sizes can be handled with this Solution

.png?width=333&height=232&name=Group%20237747%20(3).png)

Item Types Handled

Shelves can be configured to accommodate items of any shape and size

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

You need to convince your End Client.

Let us make that easy for you.

Take the first step toward earning your apparel client’s trust.

Download the exclusive Apparel Automation Kit and discover how Geekplus can transform fashion fulfillment — from fast-changing collections to seamless returns.

Why Apparel Leaders Choose Geekplus?

Modular by design

Launch fast, expand when ready

Works with any WMS

No full rip-and-replace needed

Fast payback

Typical ROI in < 2 years

Global support

40+ countries, multi-lingual ops teams

Client-level visibility

Show your customers real-time data they’ll love

Read Apparel Success Stories

Let's turn your warehouse into a growth engine 🎯

Reach out to our team for enquiries, sales, virtual demo, live demo and other informations

Downloads

F Series Product Fact Sheet

27 January, 2026

S Series Product Fact Sheet

27 January, 2026

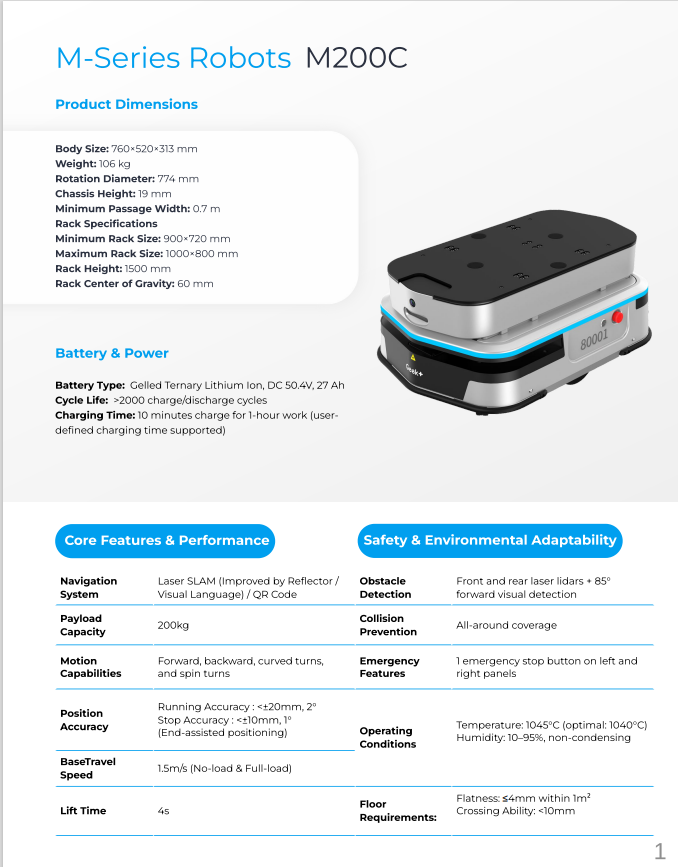

M Series Product Fact Sheet

27 January, 2026

FAQs

Geekplus solutions handle mixed storage of footwear, folded clothes, and hanging garments, while managing both B2B and B2C orders in the same warehouse. Robots sort by "same style in same tote," improving picking accuracy and enabling faster restocking for stores.

Yes, Geekplus systems are designed for flexibility. Robots can be deployed or scaled up quickly to meet high-capacity demands during peak seasons, ensuring smooth operations without delays.

Geekplus automates the returns process by subdividing shelves into return slots, allowing items to be inspected, sorted, and resold immediately. This reduces labor costs and minimizes inventory backlog, as verified by leading retailers like George.com and Bosideng.

Geekplus systems support mixed storage and dynamic shelving, maximizing vertical and horizontal space. This is especially beneficial for managing diverse SKUs and fragmented store orders in limited warehouse space.

Geekplus offers industry-leading robot system stability, ensuring smooth operations even during order fluctuations. The software is fully compatible with existing systems, and the flexible design allows the solution to grow with your business needs.

Related articles

How to Optimize Warehouse Space with ...

11 December, 2025

Black Friday at AS Watson’s: 105 Geeks and a ...

1 December, 2025

.png?width=300&height=300&name=Apparel-_0002_Next%20(1).png)

.png?width=300&height=300&name=Retail_0002_S%26S%20(1).png)

.png?width=170&height=106&name=Rectangle%20296%20(13).png)

.webp)

.webp)

.webp)

.webp)