Drogheria

Alimentate la vostra catena di approvvigionamento alimentare con velocità e precisione.

Gestite i flussi ad alto volume e mantenete ogni corsia rifornita, dai prodotti ai surgelati.

Prelevate direttamente dai pallet e dalle scatole, per una distribuzione rapida dei prodotti alimentari.

50M+

Attività orchestrate quotidianamente

1.5x

Distribuzione più rapida rispetto ai concorrenti

40,000+

Robot distribuiti in tutto il mondo

10,000+

Attività al secondo gestite da RMS

Cosa dicono i nostri clienti

.png)

Con le sfide sostanziali che il nostro team si trova ad affrontare, puntiamo a migliorare l'esperienza dei clienti e dei dipendenti reinventando la nostra supply chain grazie alle tecnologie di automazione."

Bruce Ma,

Responsabile senior della catena di approvvigionamento di Circle K

.jpg?width=800&height=450&name=Circle%20K%20video_Moment_01-1%20(1).jpg)

.png)

La collaborazione con Geek+ riflette il nostro impegno a sfruttare le tecnologie innovative per portare valore ai nostri clienti".

Linus Wong,

Amministratore delegato di Wellcome Supermarket

.webp?width=2000&height=1124&name=wellcome%20(1).webp)

Capiamo le vostre sfide

Le catene di distribuzione dei generi alimentari devono far fronte a pressioni uniche per quanto riguarda la freschezza, l'elevato turnover e i flussi complessi. Le operazioni manuali non riescono a tenere il passo.

Flusso di pallet ad alto volume

I flussi di pallet sfusi devono essere gestiti rapidamente per soddisfare il frequente rifornimento dei magazzini.

Volatilità delle SKU e promozioni

Vendite lampo, picchi stagionali e assortimenti mutevoli creano improvvise oscillazioni della domanda che mettono a dura prova le operazioni.

Operazioni a più temperature

Le zone surgelate, refrigerate e ambientali richiedono una gestione coordinata senza rallentare la produzione o mettere a rischio la qualità del prodotto.

Cicli di rifornimento frequenti

Le SKU a rotazione rapida necessitano di un rifornimento accurato e frequente per mantenere gli scaffali riforniti a livello di negozio.

Freschezza e durata di conservazione

I cicli di vita brevi dei prodotti richiedono movimenti rapidi, rotazioni accurate e tempi di sosta minimi per evitare il deterioramento.

Precisione sotto pressione

Con i margini ridotti del settore grocery, anche piccoli errori di picking o di routing portano a sprechi, perdite di vendite e insoddisfazione dei punti vendita.

Soluzioni Geek+ per ogni sfida del settore grocery

Tutte alimentate dal nostro Warehouse Execution System (WES) e dal Robot Management System (RMS) per darvi visibilità e orchestrazione in tempo reale tra zone e clienti.

Dovete convincere il vostro team? Questo kit vi aiuta a costruire il caso.

Ideale per

Centri di distribuzione di generi alimentari nazionali e regionali

Centri di distribuzione al dettaglio

Catena del freddo

Operatori ibridi B2B/B2C

Hub di micro-approvvigionamento regionali e urbani

Catene di supermercati

Operazioni di prelievo di pallet e casse ad alto volume

Hub di rifornimento dei negozi

Crossdocking

Partner unico

per la robotica di magazzino

Costruito per ogni scenario nel settore della vendita al dettaglio di generi alimentari

Ogni cliente ha i suoi canali, le sue regole e le sue promesse di consegna. Noi vi aiutiamo a passare da uno all'altro senza dover modificare le vostre operazioni. Dai pallet per la vendita al dettaglio ai pacchi DTC, Geekplus aiuta i negozi di alimentari a gestire tutto attraverso un unico flusso.

Centri di approvvigionamento che servono negozi, franchising e commercio elettronico

Nodi di micro-appagamento urbani e regionali

Distribuzione B2B per clienti in franchising, foodservice e all'ingrosso

Click-and-collect e raggruppamento degli ordini online

Automazione del retrobottega dei negozi e retrofit a basso ingombro

Stabilizzazione di SKU refrigerate e ambientali nell'inventario condiviso

Costruito per ogni processo di magazzino nel settore alimentare

Integrazione perfetta di tutti i processi per il settore 3PL. Riduzione del costo operativo per ordine fino al 40-50% e aumento della produttività di 2-4 volte senza toccare la struttura dell'edificio.

Ricezione in entrata

Acquisizione di lotto, scadenza e zona di temperatura per ogni SKU all'arrivo

Spostamenti in zone di temperatura

Inserimento automatico della merce in zone a temperatura ambiente, refrigerata o congelata

Prelievo di pezzi, casse e pallet

Supporto di tutti i formati, dal prelievo di un singolo articolo al carico completo di casse o pallet

Smistamento omnichannel

Smistamento dell'inventario per i negozi B2B o per gli ordini DTC simultaneamente

Movimento da zona a zona

Trasferimento dell'inventario tra zone a temperatura controllata senza reimballaggio

Rifornimento di scaffali e rack

Attivazione del rifornimento automatico in base a soglie di inventario per zona

Prelievo a lotti e a ondate

Combinazione di ordini simili per ottimizzare i tempi di viaggio e l'efficienza del picker

Consolidamento degli ordini

Unire le merci provenienti da diversi tipi di magazzino in un'unica unità pronta per la spedizione

Stabilizzazione in uscita per percorso o negozio

Stabilizzazione in base alla regione di consegna, alla sequenza o all'ID del negozio del cliente

Elaborazione e riassegnazione dei resi

Smistamento, controllo qualità e restituzione dei beni riutilizzabili all'inventario o preparazione per lo smaltimento

Tipi di magazzino gestiti da Solutions

Non esistono due magazzini uguali. STP si adatta all'ingombro, al mix di SKU e agli obiettivi di produttività del cliente, gestendo senza problemi ogni dimensione, forma e anche gli articoli più irregolari.

Tipi di stoccaggio

Gestito con la soluzione da scaffale a persona

Dimensioni degli articoli

Con questa soluzione è possibile gestire più dimensioni

.png?width=333&height=232&name=Group%20237747%20(3).png)

Tipi di articoli trattati

I ripiani possono essere configurati per accogliere articoli di qualsiasi forma e dimensione

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

Dovete deliziare i vostri clienti del settore alimentare. Permetteteci di rendervelo facile.

Fate il primo passo per trasformare l'evasione degli ordini nel settore grocery.

Scaricate l'esclusivo Grocery Automation Kit e scoprite come Geekplus aiuta i retailer e i distributori a semplificare le operazioni di evasione degli ordini di prodotti freschi, ambient e online con velocità e precisione.

Perché gli operatori del settore alimentare scelgono Geekplus?

Modulare per design

Avvio rapido, espansione quando è pronto

Funziona con qualsiasi WMS

Non è necessario un rip-and-replace completo

Rapido ritorno dell'investimento

ROI tipico in < 2 anni

Supporto globale

Oltre 40 paesi, team operativi multilingue

Visibilità a livello di cliente

Mostrate ai vostri clienti dati in tempo reale che ameranno

Leggi le storie di successo dell'abbigliamento

Trasformiamo il vostro magazzino in un motore di crescita 🎯

Contattate il nostro team per richieste di informazioni, vendite, demo virtuale, demo dal vivo e altro ancora.

Scaricamento

F Series Product Fact Sheet

27 gennaio, 2026

S Series Product Fact Sheet

27 gennaio, 2026

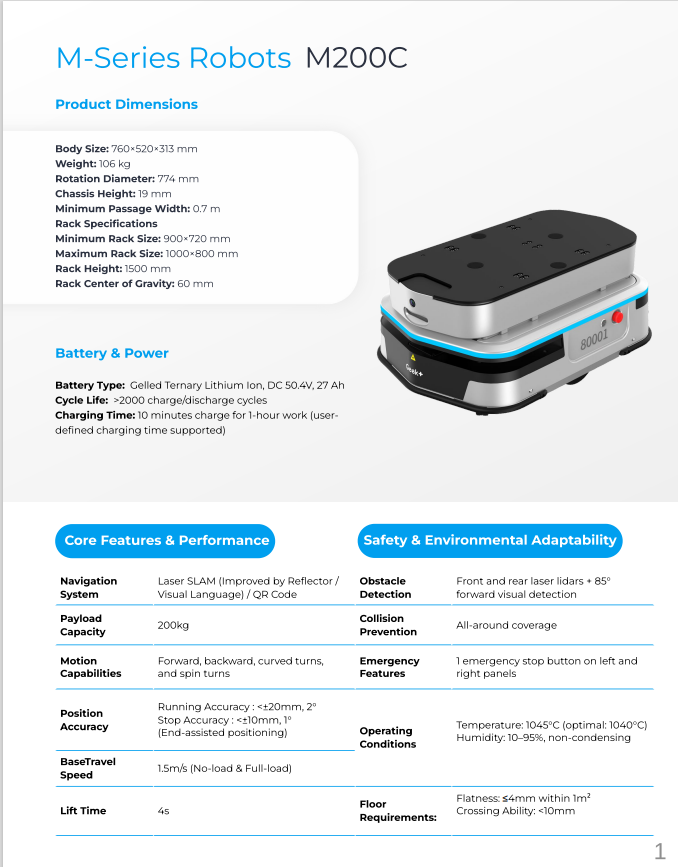

M Series Product Fact Sheet

27 gennaio, 2026

Domande frequenti

I robot Geekplus operano 24 ore su 24, 7 giorni su 7, riducendo la dipendenza dal lavoro umano. Grazie alle funzionalità di auto-ricarica e alla capacità di prelevare 300-600 unità all'ora in una singola postazione di lavoro, le soluzioni Geekplus migliorano significativamente la produttività e l'efficienza.

Sì, i sistemi Geekplus supportano il prelievo da cassette, scaffali e pallet, per accogliere articoli di ogni forma e dimensione. I prodotti ad alta richiesta sono posizionati strategicamente per un accesso più rapido, garantendo una gestione efficiente dell'inventario.

I robot Geekplus sono progettati per garantire velocità ed efficienza e consegnano fino a 350 cassette all'ora alle stazioni di prelievo. Possono inoltre operare in ambienti di stoccaggio a freddo fino a -18°C, assicurando che i prodotti deperibili vengano gestiti rapidamente e rimangano freschi.

I sistemi Geekplus utilizzano una gestione intelligente dell'inventario per organizzare le SKU in modo efficiente. Gli articoli più richiesti vengono collocati negli scaffali anteriori e inferiori, riducendo la distanza percorsa dai robot e accelerando l'evasione degli ordini.

I sistemi Geekplus sono modulari e possono essere facilmente ampliati aggiungendo altri robot per soddisfare una domanda crescente. L'implementazione è rapida, con sistemi operativi in appena due settimane.

Articoli correlati

Geek+ RMS Major Upgrade: Redefine ...

12 febbraio, 2026

How to Optimize Warehouse Space with ...

11 dicembre, 2025

.webp)

.webp)

.webp)