Healthcare & Pharma

Compliance. Secure handling. Cold chain integrity.

High-stakes inventory needs high-accuracy fulfilment. We keep your fulfilment fast, safe, and organised.

50M+

Tasks Orchestrated Daily

1.5x

Faster Deployment Compared to Competitors

40,000+

Robots Deployed Globally

10,000+

Tasks per Second Handled by RMS

What Our Customers Are Saying

.png)

We boosted throughput by 250% without hiring. It feels like the shelves do the work."

Sorin David,

Supply Chain Director of Dr. Max Romania

25 000 SKUs monthly

99.9% Accuracy

24/7 Operation

.png)

Supply Chain Manager of Medicair

600 shipments daily

Fleet of 15 AMRs

130 order lines/hour

We understand Your Challenges

Healthcare and pharmaceutical operations face growing pressure with tight regulatory standards, labor shortages, and rising demand for faster, safer delivery. Manual processes can’t keep up with the precision and traceability required.

Peak Load Surges

Black Friday, 11.11, Ramadan

Geekplus robots collaborate with humans in the warehouses, improving.

Multi-client & Multi-category Picking

Geekplus robots collaborate with humans in the warehouses, improving efficiency with.

Parcel Consolidation and Last-mile Prep

Geekplus robots collaborate with humans in the warehouses, improving efficiency with combined precision and dexterity.

High-volume Reverse Logistics

Enable efficient coordination, accurate inventory management, and proactive decision-making with software integration.

Smart Solutions for Every Pharmaceutical Challenge

All powered by our Warehouse Execution System (WES) and Robot Management System (RMS)—to give you real-time visibility and orchestration across zones and clients.

You need to meet the highest standards in Healthcare & Pharma.

Let us make that easy for you.

Ideal for

Pharma distributors

Hospital supply hubs

Medical device logistics

Cold-chain centers

Pharmacy fulfillment

& more...

One-stop Partner

for Warehouse Robotics

Built for Every Scenario in Health & Pharma

Every client brings their own channels, rules, and delivery promises. We help you switch between them without switching up your operation. From retail pallets to DTC parcels, Geekplus helps 3PLs run everything through one streamlined flow.

Hospital supply rooms and equipment warehousing

Automate receipt, replenishment, and returns for surgical kits, medicines, and hospital consumables.

National drug distribution center operations

Support high-throughput picking with compliance-ready validation and zone staging.

Online prescription order picking and verification

Optimize e-commerce fulfillment for high SKU variation with scan and audit logic.

Regulated cold chain medicine handling

Manage transfer between frozen, chilled, and ambient zones under GSP tracking.

Multi-format 2B/2C flow coordination

Unify drugstore restock, hospital demand, and e-commerce fulfillment in one layout.

Inbound receiving to outbound consolidation workflows

Streamline inbound scanning, buffer storage, batch picking, and consolidation lanes.

Built for Every Warehouse Process in Health & Pharma

Seamless integration of all processes for Health & Pharma industry. Reduce operating cost per order by up to 40-50%, and increase throughput by 2–4X without touching your building structure.

Receiving and temperature-zoned check-in

Handle inbound pallets and totes under cold chain and serial number requirements.

Putaway and traceable inventory storage

Store SKUs by temperature, expiry, and regulation compliance fields.

Order picking by batch, channel, and validation level

Pick-to-light or pick-by-scan logic ensures correct medicine, dose, and quantity.

QC, audit, and verification

Enable secure and paperless quality inspection and scanning.

Packing and outbound staging

Group by hospital, franchise, or DTC lane with shipping compliance triggers.

Storage types handled by Solutions

No two warehouses are alike. STP tailors itself to your unique footprint, SKU mix, and throughput targets—seamlessly handling every size, shape, and even the most irregular items.

Storage Types

Handled with Shelf-to-Person Solution

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

Item Sizes

Multiple sizes can be handled with this Solution

.png?width=333&height=232&name=Group%20237747%20(3).png)

Item Types Handled

Shelves can be configured to accommodate items of any shape and size

.png?width=491&height=232&name=Frame%201171275885%20(3).png)

You need to ensure accuracy and compliance in every order.

Let us make that easy for you.

Take the first step toward smarter, safer fulfillment.

Download the exclusive Healthcare & Pharma Kit and discover how Geekplus helps you automate storage, picking, and delivery while maintaining full traceability and compliance.

Why Healthcare & Pharma Operations Trust Geekplus?

Modular by design

Launch fast, expand when ready

Works with any WMS

No full rip-and-replace needed

Fast payback

Typical ROI in < 2 years

Global support

40+ countries, multi-lingual ops teams

Client-level visibility

Show your customers real-time data they’ll love

Read Pharma Success Stories

Let’s turn your warehouse into a precision-driven operation 🎯

Reach out to our team for consultations, demos, and automation insights tailored to healthcare and pharma logistics.

Downloads

Intralogistics Solution Kit

24 December, 2025

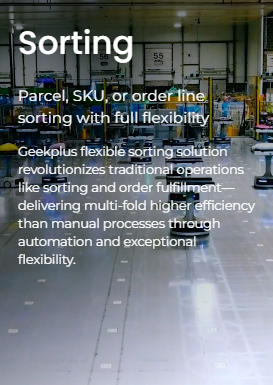

Sorting Solution Kit

11 December, 2025

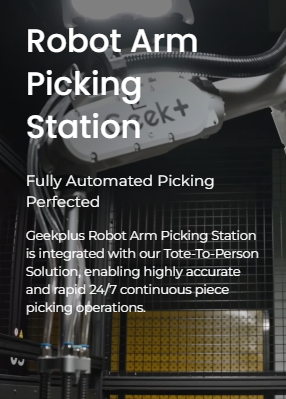

RAPS Solution Kit

11 December, 2025

FAQs

Geekplus Shelf-to-Person solutions support dynamic storage space management, allowing multiple brands and product types to be stored in the same area. Flexible shelves and smart order grouping ensure efficient picking and better storage utilization.

Yes, Geekplus systems are designed for high-speed operations. Sorting solutions enable immediate sorting upon merchandise arrival, while smart monitoring ensures accuracy and compliance with stringent time constraints.

Geekplus technology enables inventory analysis, smart tallying, and sales forecasting. This ensures precise batch picking while adhering to quantity limits, improving overall operational efficiency.

Geekplus systems eliminate the need for special storage divisions by automatically optimizing the picking and storage of similar products. Robots can be added or removed during peak times, ensuring seamless scalability and faster put-away processes.

Geekplus systems are equipped with advanced software for real-time monitoring, predictive maintenance, and compliance with industry regulations. Their flexibility and scalability ensure uninterrupted operations and adaptability to changing requirements.

Related articles

Where it all started? The Journey of ...

10 March, 2025

Industries moving forward with robotics ...

10 March, 2025

.webp)

.webp)